A common scenario often occurs in workshops: the customer arrives convinced that their battery isn't the problem because it has been recently checked or replaced.

However, the vehicle does not start. The explanation is that the starting and ignition circuit is a multifactorial system, where the battery is only the first link.

From FQS BATTERY We tell you what can happen and what systems should be checked.

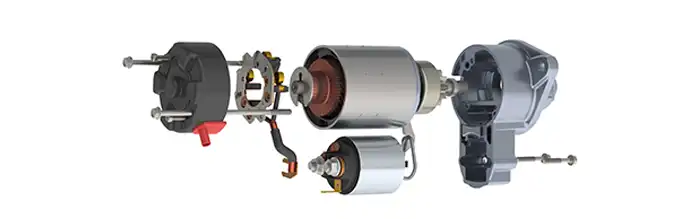

1 – Starter motor and solenoid

He starter may present:

- Wear on the collector or brushes → voltage drop and low drag torque.

- Faulty solenoid → the pinion does not mesh with the flywheel ring gear.

- Seized bearings → Excessive amperage consumption that the battery cannot sustain even when charged.

Recommended test: measurement of positive and negative voltage drops during the starting maneuver.

2 – Relays and fuses in the starter circuit

A starter relay with burned or stuck contacts prevents current flow. Similarly, a broken main fuse (usually 30–60 A in the starter line) blocks the system.

3 – Ignition switch and Start-Stop systems

The cylinder or electrical switch fails due to mechanical wear or loss of internal continuity. On vehicles with a Start/Stop button, the body control module (BCM) may not output the activation signal to the starter relay.

4 – Immobilizer and coded keys

The anti-theft system is critical: failure to recognize the transponder key blocks injection and ignition. The starter motor can turn, but the ECU (Engine Control Unit) does not enable spark or injection.

5 – Fuel supply system

- Electric pump inoperative (failure in winding, relay or fuse).

- Blockage in the fuel filter.

- Faulty pressure regulator.

Diagnostic test: injection rail pressure measurement.

6 – Timing sensors (CKP/CMP)

The crankshaft position (CKP) or camshaft position (CMP) sensor is essential. A missing or inconsistent signal prevents timing. The engine cranks but there is no fuel injection or spark.

7 – Alternator and false sensations of a charged battery

A battery may show 12.5 V at rest and yet not withstand the 200–400 A demand of the starter. This occurs when the alternator has not been charged for a long time and the battery only retains surface voltage (surface charge). Load testing is essential.

8 – Connections, grounds and sulfation

- Parasitic resistances in ground cables.

- Terminals with sulfate or poor tightening.

- Main cables with corroded internal wires.

These defects increase the internal resistance and reduce the current available at startup.

Conclusion

A failure to start with a good battery requires checking the complete system:

- Starting motor

- Control circuit (relays, fuses, switch)

- Immobilizer

- Injection

- Mass synchronization and quality sensors.

Proper diagnosis requires measuring voltage drops, starting currents and reference signals with an oscilloscope.

In short, the battery is not always to blameThe real challenge is identifying which link in the chain is interrupting the starting sequence.