Following the publication of if the batteries are discharged when stored on the groundWe have received numerous questions about the evolution of starter batteries in the automotive sector, from their origins to the present day.

Therefore, since FQS BatteryIn this article, we aim to provide a clear overview of how starter batteries have evolved over the years, highlighting the milestones and technological advances that have marked their development.

Gaston Planté's Lead-Acid Battery (1859)

Gaston Planté He invented the first rechargeable lead-acid battery in 1859. His design consisted of two coiled lead plates immersed in a sulfuric acid solution.

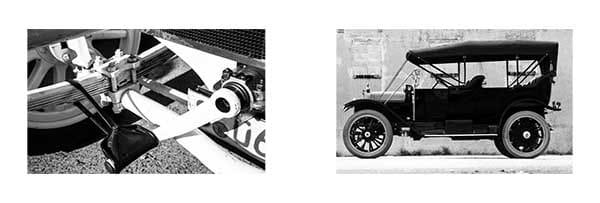

Original Design

- Structure: Two lead plates wound in a spiral, separated by cloth or rubber.

- Electrolyte: Dilute sulfuric acid, which allows the electrochemical reaction.

- Operation: During charging, lead converts to lead dioxide (PbO₂) on the positive plate and to spongy lead (Pb) on the negative plate. During discharge, the two react to form lead sulfate (PbSO₄), releasing energy.

1 – First lead-acid batteries (1912-1950)

Early automobiles had no electrical systems or starter batteries. They were started with a hand crank.

In 1912, Cadillac marked a milestone in automotive history by becoming the world's first vehicle equipped with an electric starter. Presented exclusively in the Four version and available from September 1911, this model offered six body styles and reached a total production run of 13,995 units. Its innovation became a benchmark in the technological evolution of automobiles.

At that time, the first automotive starter battery appeared. These batteries had lead-acid cells and a sulfuric acid electrolyte.

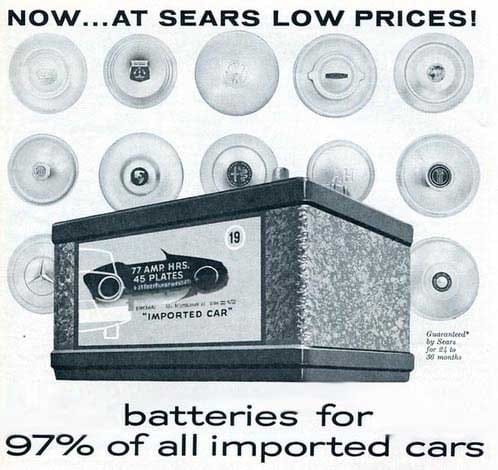

2 – Expansion and Standardization (1950-1980)

With the addition of additional electrical systems—such as lights, radios, and fans—in vehicles, the battery went from being just a starter to the primary power source for multiple devices. This led manufacturers to improve the energy density and stability of batteries. Lead alloy compositions were optimized and manufacturing processes refined to produce cells with longer lifespans, resistance to vibration, and the ability to withstand more intense charge and discharge cycles. As a result, batteries offered consistent performance, even under demanding operating conditions.

From 6V to 12V

In the early decades of automotive technology, many vehicles used 6V batteries. However, as the demand for electric power grew, a system became necessary that would allow for more efficient starting and simultaneous operation of multiple devices. The transition to a 12V system became standard for several reasons:

- Greater Starting Power: A 12V system makes starting the engine easier in adverse conditions.

- Compatibility with Complex Electrical Systems: Allows the integration of new electronic and safety equipment without compromising performance.

- Energy Optimization: Standardization facilitated mass production and maintenance, reducing costs and improving reliability in the supply chain.

3 – Maintenance-free batteries (1980-2000)

The introduction of sealed, water-free batteries represented a quantum leap in starter battery design and maintenance. These sealed batteries eliminate the need for periodic refills, reducing the risk of leaks and spills and facilitating simpler and safer maintenance, especially in environments subject to vibration and sudden movements.

In addition, improved durability was achieved thanks to improvements in the lead alloy. Optimized plate composition, which incorporated elements capable of reducing self-discharge, allowed the batteries to maintain their charge for longer periods and offer more consistent performance throughout their lifespan.

Another important advancement was the use of improved separators and reinforced internal construction. These elements minimize the formation of lead sulfate crystals (sulfation), one of the main factors that deteriorate battery capacity and performance over time. The latest generation of separators facilitate optimal electrolyte circulation, helping to preserve electrochemical efficiency and extend the device's operating life.

As for the battery housing, this component also underwent significant changes in its materials. Traditionally, housings were made from materials such as ebonite (which is a material composed of elastic rubber, among other materials) or even glass, which offered limited protection against adverse operating conditions. With the advancement of technology, high-strength plastic materials such as ABS and polypropylene were adopted.

The main improvements that were obtained with these material changes:

- Corrosion and heat resistance: These plastics are highly resistant to the corrosive action of sulfuric acid and can withstand the high temperatures generated during the loading and unloading process.

- Greater impact and durability: The new generation of housings offers improved protection against shock, vibration, and other mechanical factors, reducing the risk of breakage or deformation.

- Hermeticity and security: The precise shape of these materials allows for optimal sealing, preventing the entry of moisture or impurities that could affect the battery's internal functioning.

- Flame retardant properties: In addition, flame-retardant formulations have been incorporated to improve safety, minimizing the spread of fire in the event of overload or internal failure.

4 – GEL, AGM and LITHIUM Technology (2000-PRESENT)

- AGM (Absorbent Glass Mat) and GEL batteries appear, with greater efficiency and resistance to vibrations.

- They are used in vehicles with Start-Stop systems and high-performance vehicles.

- Electrification is driving the use of lithium-ion batteries in electric and hybrid vehicles.

- Lithium batteries are lighter, last longer, and charge faster than lead-acid batteries.

- Advances in solid-state batteries promise even further improvements in efficiency and safety, but they're not yet ready for market.

Conclusion

The evolution of vehicle starter batteries has been remarkable over the years, moving from rudimentary manual starter systems to sophisticated devices that guarantee efficiency, durability, and safety. From the introduction of the first rechargeable lead-acid batteries to the consolidation of maintenance-free AGM and GEL technologies, and the revolution represented by lithium-ion batteries, each stage has responded to the growing demands of a constantly changing automotive sector.

Today, faced with the diverse needs of the market, FQS batteries offer the ideal solution, providing the safety and performance required for traditional, high-performance, or electric vehicles. With FQS, every user can enjoy the confidence of a proven technology adapted to current and future transportation challenges.